Digital I/O Logic: NPN vs PNP

This page explains the OV80i's digital I/O configuration and how to properly wire NPN and PNP devices to the camera's M12 A-Coded 12 Pin connector.

OV80i Digital I/O Overview

Hardware Configuration

The OV80i provides 1 trigger input, 2 digital inputs, and 2 digital outputs through the M12 A-Coded 12 Pin Power I/O connector:

I/O Distribution:

- 1 Trigger Input - Primary trigger signal input

- 2 Digital Inputs - Additional sensor inputs

- 1 Digital Outputs - Result outputs

Electrical Specifications

- Operating Voltage: 19-24 VDC input

- Output Current: Max 100mA per output

- Input Logic: Pull to GND to activate input

- Output Logic: When active, output sinks to GND (NPN-compatible)

- Thermal Protection: DIO GND tied through thermal fuse

Understanding NPN vs PNP Logic

NPN (Sinking) Logic

NPN devices sink current to ground when active.

Characteristics:

- Active State: Device connects signal to GND (0V)

- Inactive State: Signal remains floating or pulled high

- Current Flow: From positive supply → through load → to device → to ground

- Common Use: Most modern industrial sensors and PLCs

PNP (Sourcing) Logic

PNP devices source current from positive supply when active.

Characteristics:

- Active State: Device connects signal to positive supply (+24V)

- Inactive State: Signal remains floating or pulled low

- Current Flow: From device → through load → to ground

- Common Use: Some European industrial equipment

OV80i Digital Input Configuration

Native Input Logic: NPN Compatible

The OV80i inputs are designed for NPN (sinking) devices.

Input Activation: Pull to GND to activate input

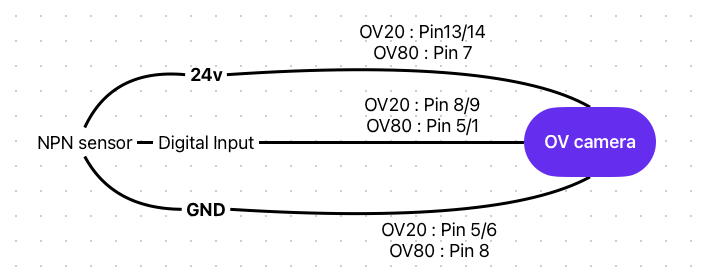

Connecting NPN Sensors (Direct Connection)

Wiring for NPN Sensors:

Operation:

- Sensor Inactive: Input floats high (inactive)

- Sensor Active: Sensor pulls input to GND (active)

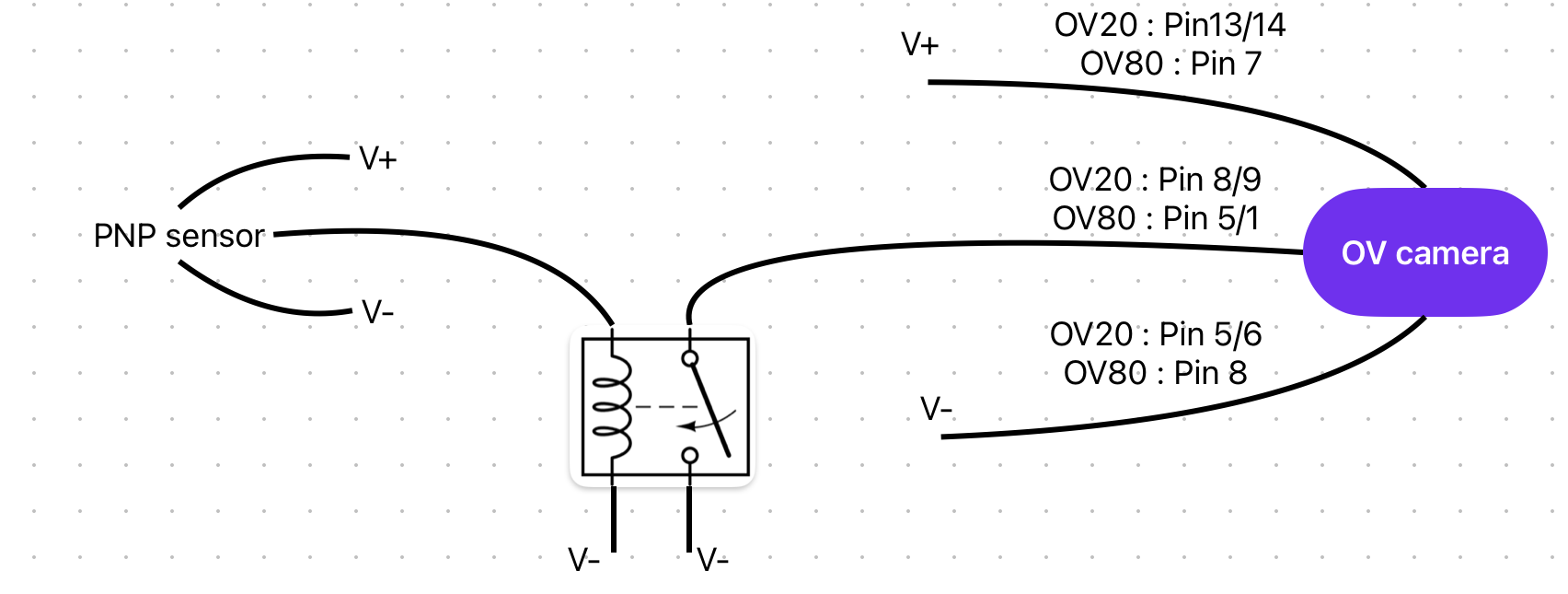

Connecting PNP Sensors (Pull-Down Required)

Pull-Down Resistor: Typically 10kΩ between input and GND

Operation:

- Sensor Inactive: Pull-down resistor holds input at GND (inactive)

- Sensor Active: Sensor overpowers pull-down, raising input voltage (may not activate reliably)

⚠️ Important: PNP sensors require additional interface circuitry for reliable operation with OV80i inputs.

OV80i Digital Output Configuration

Native Output Logic: NPN (Sinking)

The OV80i outputs are NPN-compatible sinking outputs.

Output Behavior:

- Active: Output sinks to GND (0V)

- Inactive: Output floating (high impedance)

- Max Current: 100mA per output

- External Power Required: Outputs require external power supply

Wiring for PNP Loads (Interface Required):

Interface Options:

- Relay Module: Use output to drive relay coil, relay contacts switch PNP load

- Transistor Circuit: Use output to control PNP transistor for load switching

Grounding and Common Reference

Critical Grounding Requirements

DIO GND must be connected to GND for digital input functionality to work. DIO GND is tied to GND through a thermal fuse.

Multi-Supply Systems: When connecting the OV80i's digital I/O lines to a system that is powered from a different power supply, use this pin to tie the grounds together.

⚠️ Common Wiring Issues

Ground Loop Problems

- Symptom: Erratic input behavior, false triggers

- Solution: Ensure single-point grounding, use DIO GND properly

Insufficient Output Current

- Symptom: Loads don't activate reliably

- Solution: Verify load current < 100mA, use relay for higher current loads

PNP Sensor Incompatibility

- Symptom: Inputs don't respond to PNP sensors

- Solution: Add pull-down resistors or use interface modules

Floating Inputs

- Symptom: Random triggering when no sensor connected

- Solution: Connect unused inputs to DIO GND through 10kΩ resistor

Best Practices

Design Guidelines

- ✅ Use NPN devices when possible for direct compatibility

- ✅ Verify ground connections before applying power

- ✅ Add protection (fuses/surge suppressors) for industrial environments

- ✅ Document wiring for maintenance and troubleshooting

Testing Procedures

- Verify supply voltages (19-24 VDC)

- Check continuity of ground connections

- Test inputs with multimeter before connecting sensors

- Validate outputs with appropriate loads

- Monitor current draw to ensure < 100mA per output